Equipment

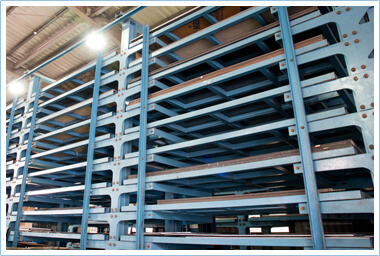

Material Preparation

Automatic Warehouse System Number of Units : 1

Brands: Developed by ourselves.

Punching

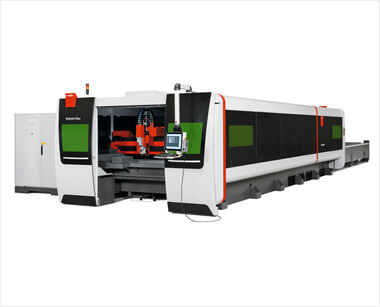

Punch / Fiber Laser Combo MachineNumber of Units : 1

| Punching Force | 33 Tons |

| Punching Operation (X/Y) | 120" x 60" |

| Laser Operation (X/Y) | 100" x 60" |

| Combined Work Area With Repositioning | 120" x 60" |

| Maximum Material Thickness | 0.250" |

NCT PunchNumber of Units : 1

PEGA-357

PEGA-357| Pressing Capability (kN) | 294 |

| Maximum Processing Thickness (mm) | 6 |

| Maximum Processing Size (mm) | 1270×3660 |

| Number of Route (S.P.M) | 350 |

| Route length(mm) | 32 |

Laser

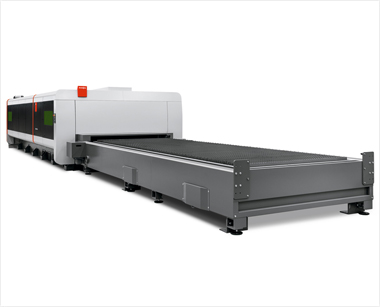

Fiber Laser Cutting MachineNumber of Units : 1

BySprint Fiber 3015

BySprint Fiber 3015| Large-sized Cutting (mm) | 3000×1500 |

| Maximum Cutting Speed (m/min) | 140 |

| Laser Source | Fiber 6000W |

| Maximum Cutting Thickness (mm) | Steel:25 Stainless steel:30 Aluminum:15 |

Punch / Fiber Laser Combo MachineNumber of Units : 1

| Punching Force | 33 Tons |

| Punching Operation (X/Y) | 120" x 60" |

| Laser Operation (X/Y) | 100" x 60" |

| Combined Work Area With Repositioning | 120" x 60" |

| Maximum Material Thickness | 0.250" |

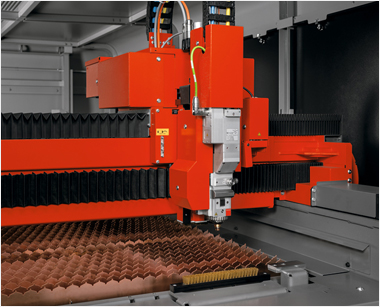

Complex Sheet and Pipe Processing MachineNumber of Units : 1

FO-MII RI 3015 AF 4000i-C

FO-MII RI 3015 AF 4000i-C| Maximum Cutting Speed | 80:80:60 |

| Maximum Cutting Size (mm) | 3070×1550×200 |

| Laser Source | AF4000i-B (rated output:4kW) |

| Maximum Cutting Thickness (mm) | Low Carbon Steel:22 Stainless Steel Sheet:12 |

| Processing Category | wide variety of tubes and beams |

| RI Processing Range (Minimum to Maximum) |

|

| Maximum Processing Weight (kg) | 200 |

| Maximum Cutting Length (mm) | 6000 |

Bending

Bending MachineNumber of Units : 2

HG8025

HG8025| Pressing Capability (kN) | 800 |

| Bending Length (mm) | 2600 |

| Route Length (mm) | 250 |

BendingNumber of Units : 1

HDS-1303NT

HDS-1303NT| Pressing Capability (kN) | 1274 |

| Bending Length (mm) | 3220 |

| Route Length (mm) | 200 |

BendingNumber of Units : 1

HFB 2204

HFB 2204| Pressing Capability (kN) | 2373 |

| Bending Length (mm) | 4400 |

| Route Length (mm) | 177 |

BendingNumber of Units : 1

FMB II-3613NT

FMB II-3613NT| Pressing Capability (kN) | 352.8 |

| Bending Length (mm) | 1300 |

| Route Length (mm) | 150 |

BendingNumber of Units : 1

RG-80

RG-80| Pressing Capability (kN) | 785 |

| Bending Length (mm) | 2400 |

| Route Length (mm) | 100 |

Welding

Automatic Argon Welding RobotNumber of Units : 1

MH6

MH6| Number of Axis | 6 |

| Position Repeatability (mm) | ±0.08 |

| Maximum Motion Range of Robot (mm) | R=1422 |

CO2 Arc Welding RobotNumber of Units : 3

FD-NB4L

FD-NB4L| Structure | Vertical articulated type |

| Number of Axis | 6 |

| Position Repeatability (mm) | ±0.08 |

| Sectional Area of Robot Motion Range | 6.37m2 x 340° |

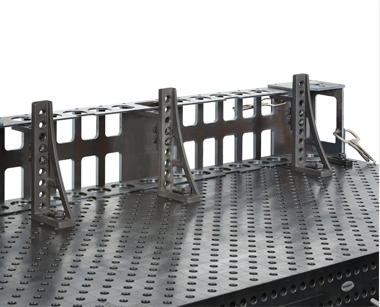

Welding Table and FixtureNumber of Units : 2

| Size (meter) | 5 x 10 |

Tapping

Automatic Tapping MachineNumber of Units : 1

CTS900NT

CTS900NT| Processing Range (mm) | X0~2700 × Y0~1100 |

| Sheet Thickness (mm) | 0.8~4.5 |

| Material | SPCC/SPHC/SUS/AL |

| Positioning Accuracy (mm) | ±0.15 |

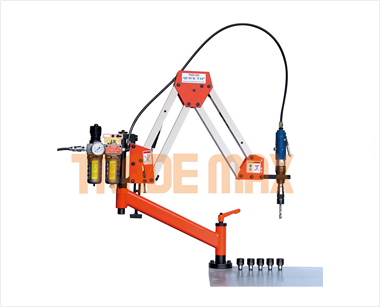

Pneumatic Tapping MachineNumber of Units : 4

AS-12、AT-20

AS-12、AT-20Packing

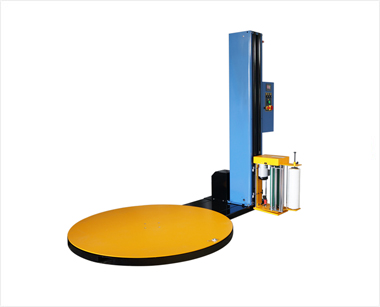

Automatic Pallet Strapping MachineNumber of Units : 1

α-2000+

α-2000+| Maximum Loading of Turntable (kg) | 2000 |

| Diameter of Turntable (mm) | 1800 |

| Maximum Height of Packing (mm) | 2200 |

Auxiliary processing equipment

| Name of Facility | Brand/Models | Number of Units |

|---|---|---|

| Shearing Machine | AMADA | 1 |

| Portable Grinding Machine | Hitachi | 30 |

| Automatic Grinder | Perfect Machine | 1 |

| Milling Machine | Manford MF-B410-FP | 1 |

| Drilling Machine | Kingsang | 3 |

| Plate Rolling Machine | JAMLCO J-0445 | 1 |

| Pipe Cutting Machine | SUMMIT SL-300N | 1 |

| Small-sized Pipe Cutting Machine | SOCO MC-275AC | 1 |